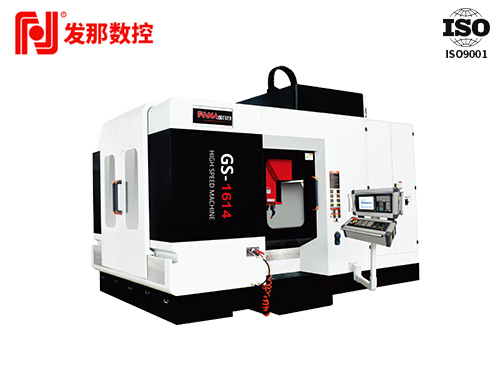

CNC gantry milling machine, gantry machining center

Shenzhen FANA CNC Machine Tool Co., Ltd

Address: 12b, Shenyun village, Shenyun Road, Nanshan District, Shenzhen

Dongguan factory address: No.2, old airport road, Baisha village, Humen Town, Dongguan City

Tel: +86 0755-29065502

Contact person: +86 13688807582

Email: export@fanacnc.com

Machine features

GS series is a high-speed gantry machining center designed and developed by FANA new generation of exclusive mold manufacturing and precision parts processing Institute. The high rigid structure design can carry high-speed milling and shorten the processing time of mold and parts.

The whole machine adopts high precision transmission parts to meet the manufacturing requirements of high speed, high precision and high efficiency.

The whole machine is made of mihanna cast iron, which is treated by stress and aging. Ensure the high precision and service life required by the machine for a long time.

technical parameter

Model | GS1190 | GS1310 | GS1614 | |

X-axis stroke | mm | 1100 | 1300 | 1600 |

Y-axis stroke | mm | 900 | 1000 | 1400 |

Z-axis stroke | mm | 500 | 500 | 700 |

Effective width of gantry | mm | 1100 | 1100 | 1410 |

Distance between spindle end face and worktable | mm | 330-830 | 330-830 | 250-950 |

Table size | mm | 1100x900 | 1400*900 | 1700x 300 |

T-groove (width x spacing x quantity) | mm | 5x18x175 | 5x18x175 | 7x22x185 |

Max capacity | Kg | 1000 | 2000 | 4000 |

Driving mode | Direct connection of main shaft | |||

Maximum spindle speed | rpm | 15000 | ||

Spindle power | kW | 11.7 | 11.7 | 20 |

Spindle torque | NM | 34/46 | 34/46 | 58/82 |

Spindle taper hole | HSK-A63 | HSK-A63 | HSK-A63 | |

Fast moving speed | m/min | 24/24/20 | 24/24/20 | 20/20/15 |

Maximum cutting speed X / Y / Z | m/min | 10 | 10 | 10 |

Magazine capacity | T | 24 | ||

Control system | Siemens | |||

Machine weight | T | 8 | 9.5 | 14 |

Machine dimensions | mm | 3200×2200×2700 | 3500×2200×2900 | 4900×3152×3350 |

Standard configuration: | Optional configuration: |

1.CNC system: Siemens 828d | 1.CNC system: Mitsubishi m80a. FANUC 0I |

2.Spindle constant temperature cooling system | 2.Motorized spindle 20000rpm (hsk-a63) |

3.Pneumatic, centralized lubrication system | 3.Disc 24 mechanical tool magazine (hsk-a63) |

4.Full protection of machine tool with top | 4.Spindle ring spray cooling |

5.Tricolor lamp | 5.CNC indexing table (fourth axis) |

6.Standard attachments and related documents | 6.Automatic measuring device for workpiece (2D) |

7.Common maintenance tools | 7.Automatic tool measuring device |

8.Screw chip removal device | 8.Oil water separation unit |

9.Electric cabinet air conditioner | 9.Grating ruler (full closed loop) |