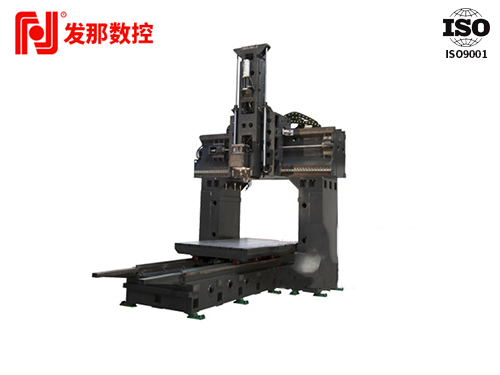

CNC gantry milling machine, gantry machining center

Shenzhen FANA CNC Machine Tool Co., Ltd

Address: 12b, Shenyun village, Shenyun Road, Nanshan District, Shenzhen

Dongguan factory address: No.2, old airport road, Baisha village, Humen Town, Dongguan City

Tel: +86 0755-29065502

Contact person: +86 13688807582

Email: export@fanacnc.com

Description of main technical features

1. The advanced design concept of Germany is introduced, and the mechanical analysis is carried out by finite element method. The reasonable distribution of reinforcement and reasonable distribution quality make the machine tool have strong rigidity, stable static precision and dynamic performance. It is an advanced equipment with high efficiency, high precision and high reliability.

2. The machine bed, table and other large parts are made of high quality resin sand and cast iron, which makes the machine tool obtain high rigidity and long-term stability precision. After sufficient secondary aging treatment (tempering and vibration aging), it can guarantee the stability of long-term performance of machine tool.

3. The three axes are Taiwan heavy load linear guide rails, which have strong rigidity and good dynamic performance. The z-axis adopts rectangular slider, which is of strong rigidity and high stability.

4. The two ends are fixed with pre stretching structure, which is compact, stable in motion and high in precision.

5. The cross beam adopts stepped structure, with large cross-section and large span of guide rail. The distance between the center of the main shaft and the guide rail surface of Z axis is designed as the shortest, the turning torque is small and the structure rigidity is good.

6. The main transmission structure is: the AC servo motor is directly connected through coupling, and the power is transmitted to the ball screw pair. The screw nut is connected with the sliding seat of the machine tool spindle box, and the spindle box is driven to move rapidly by the rotation of the servo motor.

7. The main shaft box is the patented linear rail structure spindle box (this structure has the characteristics of high precision, fast speed and high efficiency, and is suitable for castings, ordinary steel parts and other workpieces requiring high precision machine tool processing):

8. The main shaft box is equipped with nitrogen balance cylinder on both sides to ensure smooth and stable movement of the main shaft box;

9. High speed, high precision, high rigidity heavy load spindle unit is adopted, with strong axial and radial bearing capacity, and the maximum bearing speed can reach 6000rpm. The main drive adopts gear belt or straight coupling or reducer to drive to the main shaft at variable speed;

10. The guide rail and screw adopt centralized timing and quantitative centralized lubrication system to supply oil periodically to each lubricating point, so as to ensure the flexible and reliable moving parts.

11. The main shaft bearing and screw bearing are imported high-speed and low temperature grease, which can be lubricated for a long time and reliable in motion.

Main technical parameters of Optics and mechanics

Model / Project | 2722H/2722HE | 3222H/3222HE | |

Table size (width) × (long)(mm) | 1800×2700 | 1800×3200 | |

Table load bearing (T) | 9 | 10 | |

Table travel direction (x-axis, mm) | 2700 | 3200 | |

Sliding seat travel direction (Y-axis mm) | 2200 | ||

Spindle up and down travel direction (Z axis mm) | 1000 | ||

Gantry width (mm) | 2300 | ||

Distance between spindle end face and worktable (mm) | 100-1100 | ||

T-groove (number size) × Spacing) | 11-22 * 175 (the distance between the two T-grooves on the outermost side is 150) | ||

Spindle specification (model / mounting diameter) | BT50/ Φ 190 belt type (speed ratio: 2:3 or 1:1) | ||

Spindle speed rpm / min | Maximum speed of spindle bearing: 6000 (actual speed of tool: 4500 or 6000) | ||

Specification of XYZ axis ball screw | X:6316; Y:6316; Z:5008 | ||

XY axis guide specifications | X-axis: 55 heavy-duty ball track; Y-axis: 55 heavy duty roller track | ||

Z-axis guide rail specification | 55 heavy duty ball line rail (FANA patented four line rail headstock) | ||

Servo transmission mode and transmission ratio of feed shaft | Standard configuration: direct connection, optional reducer structure: X: 1:3; Y: 1:3; Z: 1:3; | ||

Spindle specification (model / mounting diameter) he series | Standard configuration: BT50/ Φ 190 belt type (speed ratio: 2:3 or 1:1) with direct spindle | ||

Spindle specification (model / installation diameter) H series | Standard configuration: BT50/ Φ 190 gear type | ||

Spindle motor, feed servo motor configuration | Recommendation: spindle motor: 15kw; X:30Nm; Y:30Nm; Z: 30nm band brake | Recommendation: spindle motor: 15kw; X:30Nm; Y:30Nm; Z: 30nm band brake | |

XYZ three axis fast movement (mm/min) | XY axis: 10000mm, Z axis: 8000mm | ||

Optical mechanical weight (T) ± 5% | 25 | 32 | |

Optical machine main configuration:

1. Machine bed is resin sand casting

2. Gantry milling head: gear type milling head (H Series), belt milling head (he Series) or optional straight joint milling head

3. Taiwan main shaft (moment will, number of grid), including spindle motor pulley and spindle belt

4. Imported ball screw and precision lock nut (screw rod: Taiwan Shangyin, Yintai C3 class 0.008/300mm)

5. Imported linear guide rail (HIWIN or PMI in Taiwan);

6. Inlet coupling (r+w or KBK)

7. Imported bearing for screw rod (NSK or Nachi, Japan)

8. Domestic hydraulic nitrogen balance system for spindle box

9. Paint: can be configured according to customer requirements (color plate), paint color

10. Lubrication system (Shengxiang)

11. Guide rail steel shield and organ guard